Best Practices

MEDICAL CHILLER BEST PRACTICS

MEDICAL CHILLER BEST PRACTICS

You made a significant investment in your MRI. You need maximum up-time from your chiller. Read these best practices for chiller installation and maintenance so you minimize costly down time on your MRI in the future.

Proper Siting and Installation

Distance:

A chiller has a maximum distance that it can be located from the MRI. Flow rate and temperature decrease the further you get away from the chiller. Distance above the MRI and below the MRI will also affect how hard the pump needs to work in order to provide the right flow needed for the MRI. Ensure that you follow the manufacturers installation instructions and recommendations, particularly for locating of the chiller. Also consider installing a city water bypass in case your chiller needs service.

AirFlow Circulation and Facing of the Condenser:

Just like any HVAC equipment, heat from the MRI is carried away by the outbound coolant and is dissipated to the environment via the chiller's condenser. If the condenser is subject to high ambient temperatures from either direct sun, other HVAC equipment blowing hot air into the fins, or insufficient air circulation around the chiller, the chiller's ability to cool your MRI is reduced. You may not notice it on a cooler day, but when it's over 125 degF on the rooftop, cooling power will be decreased. This is just the natural laws of physics.

City Water Bypass:

All chillers will require maintenance at some point. Installation of a city water bypass is highly recommended to allow your service team to work on the chiller without having to shut down the MRI. Ensure this is designed correctly with proper flow rate and drainage. Also be sure to label all valves so there are no accidental overflow/dump of coolant because of someone incorrectly opening/closing valves.

Regular and Proper Maintenance

Any HVAC equipment needs regular maintenance to keep it operating reliably over the lifespan of the unit. Every chiller requires at least two services per year to keep it operating in top condition. It is important to check for refrigerant leaks, coolant leaks, and clean the condenser coils. Depending upon your local environment, a chiller's condenser coils may need cleaning 2 to 3 times per year. With regular maintenance, your chiller should last well past it's published end of service life.

Condenser:

Cleaning of dust and debris from the condenser coil fins is vitally important to maintain the most efficient heat rejection to the atmosphere. Air flowing over the fins pulls the heat away from the chiller. If the effective surface area is reduced due to build up of dirt film or other contaminants, the cooling power is also reduced. Ensure that the coil fins are washed in the direction opposite the air flow. You may also need to consider certain times of the year where heavy pollen is sucked into the condenser coil. Extra cleaning may be needed.

Leak check - Refrigerant and Coolant:

Fluid is the medium by which heat is transferred away from your MRI. If you lose a critical amount of either refrigerant or coolant, your MRI might not be cooled adequately. Small leaks that go unnoticed can develop into bigger problems later on. Having this checked by a qualified service technician at the regular service interval is an important step.

Compressor/Pump Loads:

How well the chiller's rotating equipment is performing can indicate future problems. To the trained technician, reading of the voltage and current from the pumps and compressors can foretell any imbalance which could lead to premature failure and costly down time.

The most important point in any chiller maintenance program is to hire an experienced and knowledgeable company who knows how to service MRI chillers. Just using an ordinary residential HVAC contractor could put you and your MRI at risk.

When to Replace Your Chiller

A chiller usually has a manufacturer recommended end of service life (EOSL). Depending upon how well a chiller is maintained, it could still work reliably to cool your MRI. Questions that should be asked in determining if you need to change your chiller are:

- Is the chiller properly cooling?

- How many service incidents has the chiller had over the past 24 months?

- Was the chiller regularly serviced at the recommended intervals, using OEM parts and following all manufacturer recommended procedures?

- Was the chiller subject to any weather extremes or repeated electrical surge events?

If your chiller is nearing EOSL, and any of these factors have negatively impacted the chiller reliability, then it may be better to replace your chiller now to avoid expensive down time in the future. Investment in a new chiller is small in comparison to the cost of major repair to your MRI or replacement of your MRI.

If you need help to evaluate your chiller's condition, please contact us at 1-800-713-1543. We will be happy to provide a recommendation over the phone with a little bit of information and history.

The Importance of Picking the Right Chiller

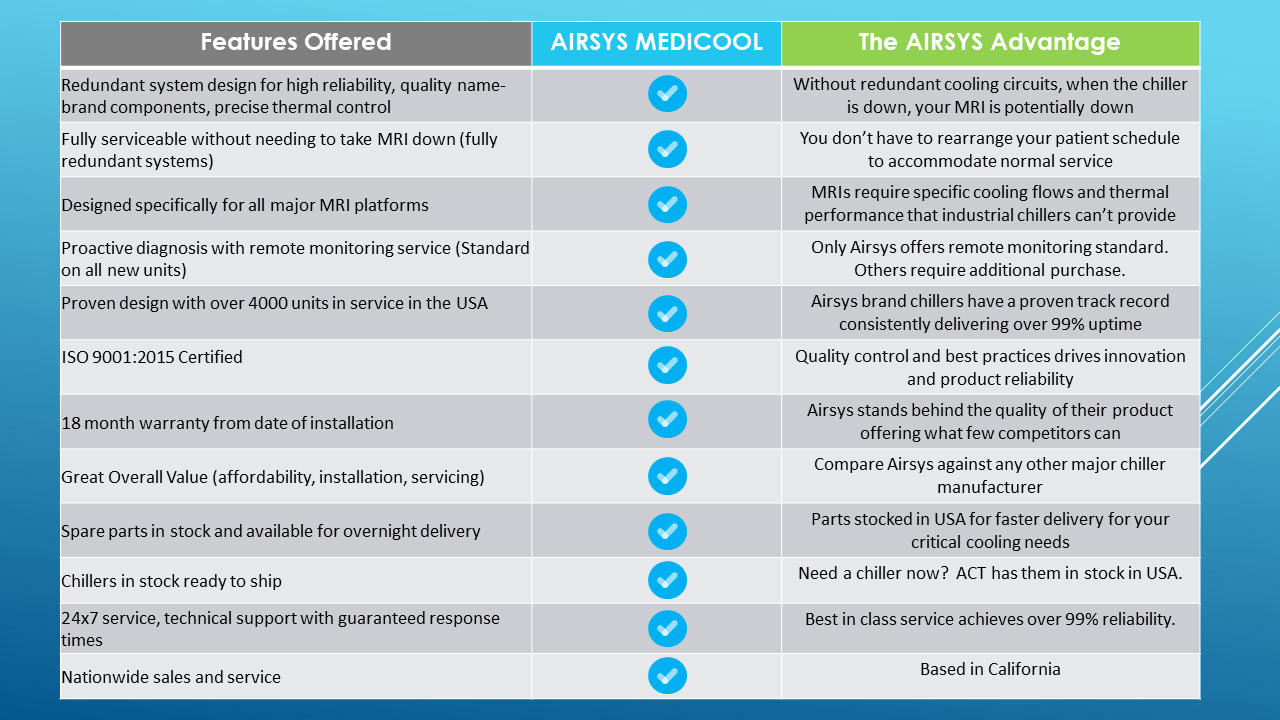

So why purchase a chiller designed specifically for MRI cooling?

- MRI’s are expensive pieces of equipment that need proper cooling to function well.

- MRI chillers are built with higher reliability requirements, minimizing the possibility of down time

- MRI chillers are specifically designed for the duty cycle of MRI scanning. Cooling is better controlled, and large temperature swings are eliminated.

An MRI can be a critical component in making an accurate medical diagnosis. Having an MRI chiller go down may result in the MRI itself being down. Just because a chiller has a cooling capacity that matches the MRI’s requirement, it doesn’t mean it will meet the total demand of an MRI. Look for brands such as Airsys Medicool which are designed for the service duty of MRIs.

Always Choose a Qualified Installer

Even if you have picked the right chiller, you could still face problems and lower reliability if the installation is not correctly. You need to consider all of the manufacturer siting requirements, proper ventilation, proper coolant flows, and if your service team is qualified to do the work. AIRSYS' recommendations are:

- Obtain service only from an experienced installer who knows specifically about medical cooling and MRI requirements

- Know the chiller manufacturer's specific requirements for installation - distance from MRI, elevation, air flow, etc

- Read the chiller instruction manual

- Use chillers specifically designed for MRI application

- Set up regular maintenance from service teams experienced and certified to perform service on the equipment

Need Help?

Let the experts at ACT help you navigate the world of MRI chillers. We can recommend a chiller to meet your specific needs, and maintenance plans to keep your MRI running trouble-free. Our service engineers are experts in medical cooling technologies.

Contact Us

Sales: 925-997-7399

Service: 1-800-713-1543, Option 2

Visit Us

Contact Us

Location:

3151 Independence Dr, Livermore CA 94551-7595, United States

Call us:

+1 800 713 1543

+1 800 713 1543

E-mail:

sales@advancedcoolingtech.com

sales@advancedcoolingtech.com

ACT © Copyright 2019